Blog

Differential Pressure Transmitters: How Do They Help in Flow Measurements?

Differential Pressure Transmitters: How Do They Help in Flow Measurements?

July 17, 2017

Flow measurement is basically the process of determining the fluid flow in a plant or an industry. This measurement can be done with the help of various devices, such as positive displacement meters, differential pressure transmitters, Coriolis, magnetic meters, etc. However, differential pressure transmitters are being used on a large scale for flow measurement in various industries. These flowmeters can either be used as gas flowmeters or liquid flowmeters. Different types of differential pressure transmitters are used for based on the application requirements. In this post, we will shed some light upon the working of differential pressure flowmeters and their types.

How Do Differential Pressure Transmitters Measure the Fluid Flow?

The working of differential pressure (DP) flowmeters is based on the Bernoulli’s principle. Here is the working principle of a differential pressure flow transmitter explained in a few, easy-to-understand steps:

- Step 1: A compression is created in the pipe by the differential pressure flowmeter.

- Step 2: A pressure drop is created in the flowmeter because of this constriction.

- Step 3: This pressure drop increases with the increase in the fluid flow.

- Step 4: The upstream and downstream pressures are routed to the differential pressure transmitter by impulse piping.

- Step 5: This differential pressure is then measured by the transmitter and fluid flow is determined.

What are the Types of Differential Pressure Flowmeters?

Based on the measurement, different types of differential pressure flowmeters are used. Here are a few types of DP flowmeters.

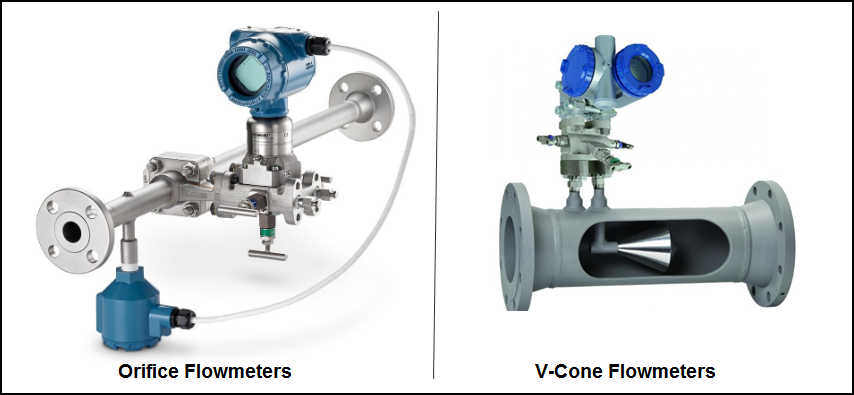

- Orifice Flowmeters: The orifice flowmeters consist of a flat metal plate, with an opening. This flat plate is installed in a circular pipe, and is perpendicular to the flowing fluid. When the fluid passes through the opening (orifice), a restriction is caused, which decreases the pressure and increases the velocity of the flow. The pressure between the pipe flow stream and the orifice is measured by a differential pressure transmitter.

- Pitot – Static Tube Flowmeters: These flowmeters consist of annular tube, pitot tube, and static pressure ports. The pitot tube converts the kinetic energy of the fluid flow into potential energy to determine the local velocity at a point in the flow stream.

- V-Cone Flowmeters: As the name suggests, these flowmeters consist of a V-shaped cone element. It is placed in the center of the pipe to create an annular space for passing the fluid. This conditions the fluid flow and creates a differential pressure. It enables easier and less noisy measurement of the differential pressure as compared to that done by orifice technology. The pressure before the cone and after the cone is measured with the help of a differential pressure transmitter.

There are other types of flowmeters too, such as elbow, wedge, spring-loaded variable aperture, nozzle, venturi, and laminar flowmeters. Hope the post helped you in understanding how the differential pressure transmitters work. Also, the information about the different types of differential pressure flowmeters will help you select the right one for your flow measurements. If you are confused in selecting the right type of transmitter for your application, you can seek advice from an expert. The Transmitter Shop is one such expert, which provides wide varieties of reliable differential pressure transmitters, such as Foxboro transmitters, and Rosemount transmitters.

- Comparison between Multi Valve Manifolds Block Valves and Bleed Valves

- Understanding Electrochemical Detection: Principles, Techniques and Environmental Application

- How Can Greenhouse Gas Emissions Be Reduced?

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- Understanding Electrochemical Detection: Principles, Techniques and Environmental Application

- How Can Greenhouse Gas Emissions Be Reduced?

- Pneumatic Pressure Controllers: A Safe Choice for Hazardous Areas

- A Practical Guide to Vacuum Measurement and Operation

- An Unconventional Guide to Selecting the Right Pressure Sensor

QUICK ENQUIRY